Vegan production

Development of vegan production systems - Scale-up requirements in plant engineering

The constant evolution in the field of vegan products places ever greater demands on plant engineering. The introduction of new protein sources and raw materials in particular not only gives rise to new ideas, but also technological challenges that need to be carefully considered from the outset. Ruland Engineering contributes its extensive expertise in plant engineering to ensure the successful development and production of vegan products.

Focus on the overall process

System design crucial right from the start

When developing vegan products, a holistic understanding of the entire manufacturing process is crucial. We attach great importance to understanding the limits and restrictions on all scales up to industrial production. In addition to technologically and economically optimised processes, quality-determining physical factors such as temperature, fixation and cutting are also integrated into the design of the process.

Risk assessment and project planning

The key to success in plant engineering

The assessment of project risks is an integral part of our approach. After successful laboratory tests, we not only analyse which technologies and parameters can be implemented on an industrial scale. The question also arises as to how the raw material is processed, whether there are parallel process steps or whether observations have already been made as to which steps have a direct impact on quality. Once the manufacturing process has been fully described and the critical factors identified, the design phase begins. Here, the risk assessment covers the aspects of market launch, productivity and food safety. How successful is the product and what prices can be achieved? Although hygiene measures are associated with costs, the risks of contamination and spread through recalls, imported allergens and other contaminants can be very expensive and, above all, damage a company’s reputation. The aim is to comprehensively weigh up acceptable risks while controlling project costs.

Always stay clean

Hygienic process validation

Die Sauberkeit jeder Prozessanlage ist entscheidend für den Erfolg. Ruland Engineering setzt dabei auf eine effektive hygieneseitige Prozessabsicherung. Klare Reinigungsanforderungen werden definiert, und Reinigungsprogramme werden je nach Medien, Temperaturen und Konzentrationen optimiert. Dies gewährleistet zuverlässig das gewünschte Hygieneniveau. Die Überprüfung der Reinigungsergebnisse erfolgt durch verschiedene Methoden wie Waschwasserkontrolle, ATP-Messung, Riboflavintest oder mikrobiologische Validierung.

Scale-up and pilot scale

Safety through experience

Careful plant and process design is followed by test runs on a semi-industrial pilot scale. We offer various approaches here. Be it through co-operation with professional development partners or by investing in our own test facilities. The successful pilot scale forms the basis for the design of the actual production plant.

Focus on important plant areas

Sustainability through precise planning

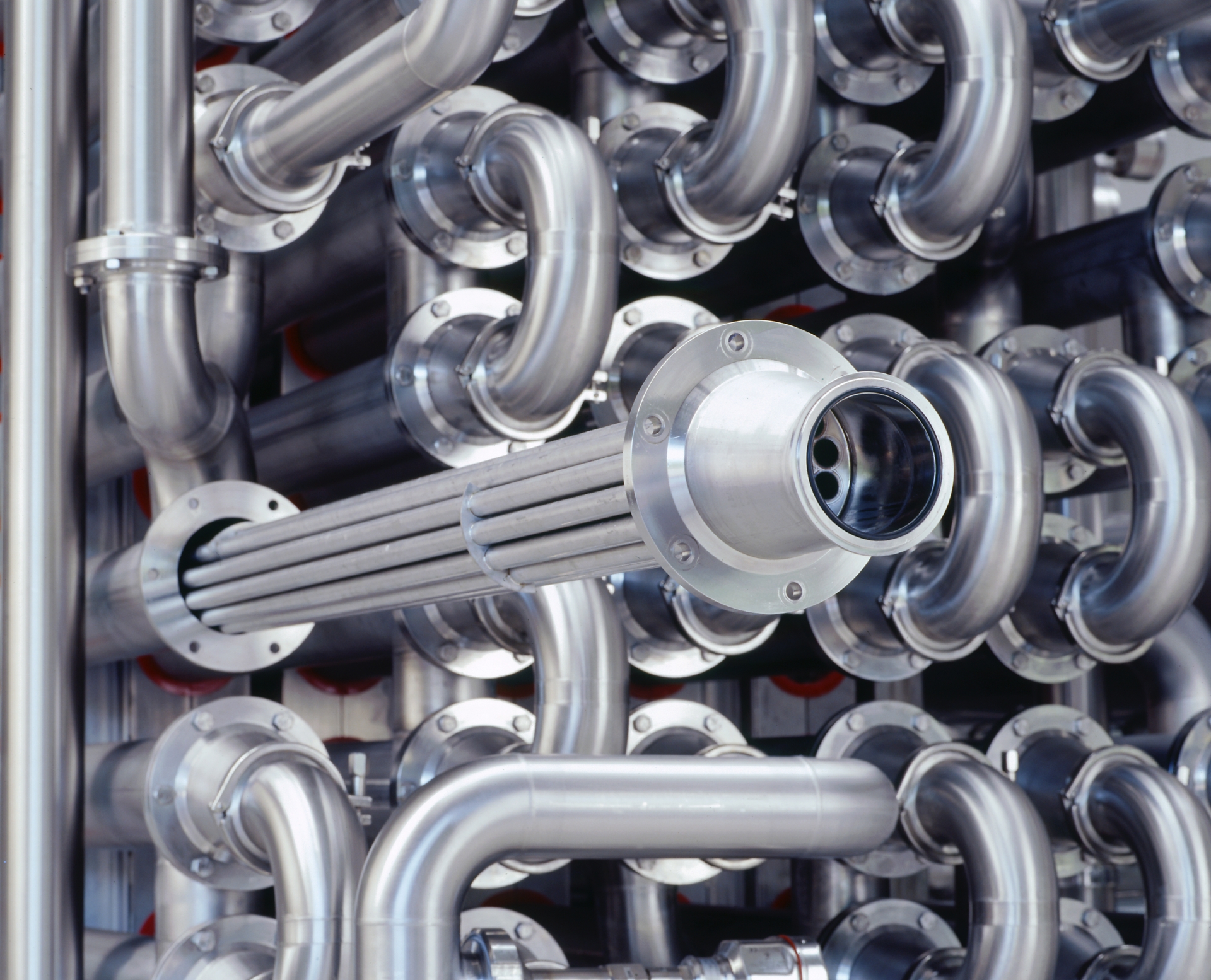

Ideal conditions are created for the realisation of processes with enzymes, cultures or other microorganisms. Ruland Engineering takes the actual requirements into account and equips the fermenter accordingly. Precise planning is also crucial for dosing and mixing equipment in order to guarantee standardised products and compensate for fluctuations in raw materials. The media supply infrastructure is carefully dimensioned so as not to impair the performance of the plant.

Want to know more about vegan production systems?

Ruland offers innovative solutions in plant engineering

Ruland Engineering has been a reliable partner in plant engineering for more than two decades. With perfect project management, prudence, foresight, comprehensive expertise and many years of experience, we plan innovative plants. We understand the products and the factors influencing quality and yield, and our holistic approach ensures the success of your projects. Contact us to help you master the challenges of plant engineering for the development of vegan products. We not only offer functioning and profitable process plants, but also the security of a partner who is at your side during planning and implementation.