Plant engineering for the beverage and juice production

Customized process solutions for maximum quality and efficiency

The production of beverages and juices places high demands on hygiene, process stability and product quality. Whether fruit juice, syrup, soft drinks, fermented products or teas – each product requires an individual plant concept that optimally combines technology, recipe and process parameters. For decades, our plant experts have been developing tailor-made process solutions for the beverage industry. Precisely planned, reliably automated and hygienically implemented. Our strength lies in our deep understanding of the industry. We know the requirements from the perspective of product manufacturers – from family businesses to multinational corporations. This knowledge flows into every phase of our projects: from concept to detailed engineering to commissioning. Our solutions are based on sound process engineering, many years of project experience and a clear focus on efficiency and quality.

Industry expertise

at every stage of production

Our systems cover the entire process range – from raw material reception to preparation for filling. We always take a holistic view of processes and consider each system in conjunction with upstream and downstream steps. The result: consistent, flexible and scalable system solutions that are precisely tailored to production requirements. Typical process steps that we implement with our own engineering expertise:

- Batch systems for the production of fruit juices, nectars, teas and syrups

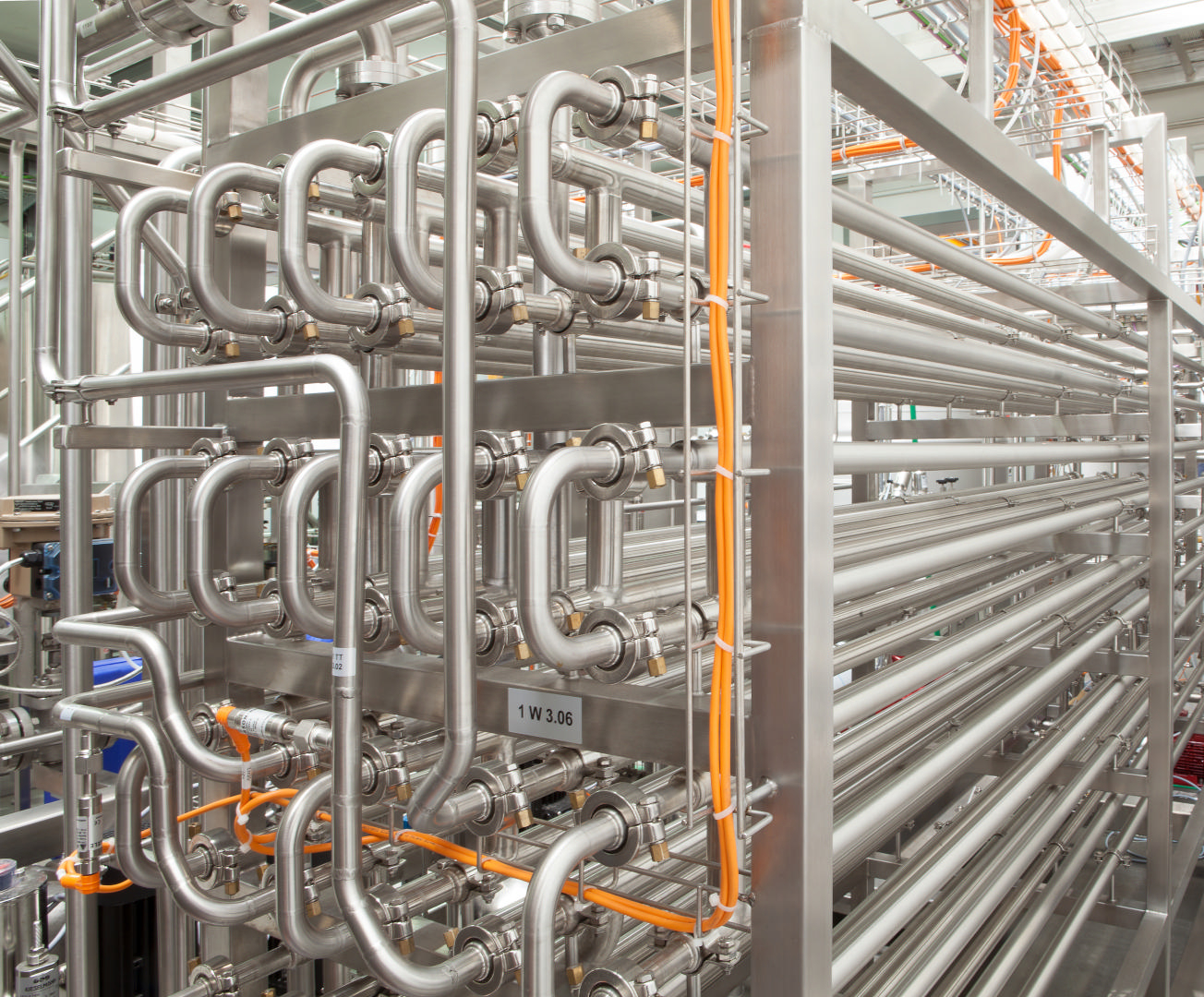

- Heat exchanger solutions such as tube and plate heat exchangers

- UHT (ultra-high temperature) systems for heating sensitive products

- CIP and SIP systems for reproducible cleaning and disinfection

- Product storage with intelligent tank management and media switching

- Aseptic process control with sterile valve blocks

- Flavor dosing and inline dilution directly in the process

- Blending and mixing systems for the precise mixing of raw materials

Raw material acceptance and storage: The first step toward quality assurance

Hygienic and safe storage solutions for liquid raw materials

The quality process begins as soon as the goods are delivered. We supply customized systems for receiving and temporarily storing liquid raw materials in a hygienic and safe manner. Whether tank trucks, IBCs or barrels – we design efficient and hygienic unloading and storage systems. Our tank farms comply with modern EHEDG standards and ensure safe and product-friendly handling. Together with our customers, we lay the foundation for sustainable production and the highest quality right from the early stages of production.

Precise mixing technology for perfect recipes

Precise dosing and optimal processing for maximum product quality

Precise mixing systems are essential for the exact mixing of ingredients. Ruland offers both classic systems for mixing and dosing raw materials and fully automated systems for batch or continuous operation. Our mixing systems, such as the flexible powder dissolving and dosing station, ensure precise dosing and optimal preparation of solids. Innovative control systems and continuous process optimization ensure consistent product quality while reducing energy consumption and material costs.

Degassing for stable taste and longer shelf life

Effective oxygen reduction to prevent oxidation

Oxygen in the product leads to oxidation, changes in taste and a shorter shelf life. Our vacuum degassing systems effectively reduce the oxygen content, thereby protecting color, aroma, and nutrients. The result: longer shelf life, stable recipes and a consistently fresh taste experience.

Pasteurization and aseptic processing for maximum product safety

Gentle heating to reduce bacteria while maintaining consistent quality

We rely on pasteurization technologies to ensure the microbiological safety of beverages. Our systems gently heat beverages and juices, killing harmful microorganisms while preserving the sensory properties of the product. In combination with aseptic process technology, our heating systems enable contamination-free processing. This increases shelf life and product safety while maintaining consistent quality.

CIP systems – reliable cleaning for reproducible quality

Automated cleaning processes for safe production

Cleanliness is non-negotiable in beverage and juice production. Our CIP (Cleaning in Place) systems guarantee safe, automated cleaning of all plant components that come into contact with the product – efficiently, documentably and reproducibly. We plan and implement our CIP systems precisely tailored to the product, process and production volume. Whether single- or multi-circuit systems, cold or hot, with alkalis, acids or water – every system is hygienically optimized and designed for short cleaning cycles. Thanks to intelligent design, precise control, and effective media management, our customers save cleaning time, water, chemicals and energy. At the same time, our CIP systems ensure consistent product quality with maximum plant availability.

Automation for maximum efficiency

Overview and control with the Ruland Process Management System (RPMS)

A stable, efficient process thrives on transparent control. Our automation technology ensures safe, traceable production. This includes end-to-end process visualization, intelligent batch management and connection to existing systems. We rely on proven control platforms (e.g., Siemens, Rockwell) and develop customer-specific solutions with open system design. Our Ruland Process Management acts as an MES system and can be integrated into existing MES or ERP systems. Complete documentation of all production processes and traceability round off the RPMS portfolio.

Your partner for innovative beverage and juice production

Complex process solutions with experience and expertise

With Ruland Engineering & Consulting as a partner, beverage and juice producers benefit from customized solutions that ensure the highest product quality, efficiency and safety in production. Our many years of experience and comprehensive expertise make our company a reliable partner for the beverage industry. Through continuous research and development, we also ensure that our solutions always meet the latest technological standards in order to meet the constantly changing requirements of the industry. With our extensive experience in plant engineering for beverage and food processes, we support our customers worldwide – from engineering to commissioning. Our projects range from expansions of existing lines to greenfield projects on an industrial scale. Our interdisciplinary team of process engineers, electrical engineers, automation specialists and project managers from a wide range of industries ensures that every plant functions technically, and also impresses in everyday production with the highest product quality, efficiency and safety.

You are planning a new system?

Or would you like to further develop existing systems?

Talk to us – we take a holistic approach to processes and implement them with technical perfection. We look forward to hearing about your project!