Virtual reality: model-based planning for process plants

3D model or VR glasses?

Three-dimensional models create a realistic visualization of process systems even before they are physically manufactured. Although 3D drawings are a powerful tool for optimizing the design process, VR glasses offers far greater possibilities. Designing process equipment for the food and beverage industry requires special attention to details in optimal use of space, correct planning of piping and ensuring easy access for maintenance of components. In this context, virtual reality technology represents a major advantage.

Visit the site in virtual reality

Virtual prototyping and design

We use VR glasses primarily for virtual prototyping and the design of process plants. The CAD design department and the project engineer create a 3D model of the plant prototype, which can be viewed and inspected in a virtual environment based on the actual installation site. The glasses also allow interaction with the model and enables a better understanding of space, proportions and functionality of the designed object. The project engineers can discuss the detailed model with the client. A meeting in virtual space provides an opportunity to take into account the specific expectations of the contractor, who can point out elements that require correction. In this way, we can identify and correct potential problems during the implementation of the project and avoid costly changes during the construction phase.

Practical applications of VR

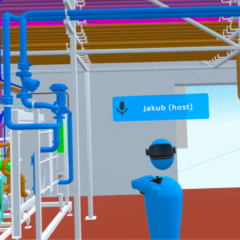

Improving communication and collaboration

The use of VR glasses makes the barrier of different project team locations irrelevant. Everyone involved in the design process works on the same virtual model at the same time, regardless of where they are located.

VR makes maintenance easier

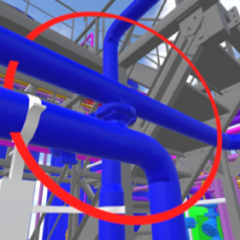

Maintenance and servicing

VR glasses also offer great potential to support maintenance work in real time. In the near future, our customers’ maintenance specialists will receive remote support from Ruland experts with the help of VR glasses. By observing what is happening on site and superimposing the virtual image on the real image, precise instructions can be given. This will significantly speed up the process of repairing or maintaining process plants. In this way, it is possible to react even faster and more efficiently to malfunctions, minimizing downtime and the associated costs.

See you in virtual reality!

Contact us! We would be happy to share our experience and show you how VR glasses can support your plant construction project right from the engineering phase.