Optimising the yield

Batch separation: Pigging and Whirlwind

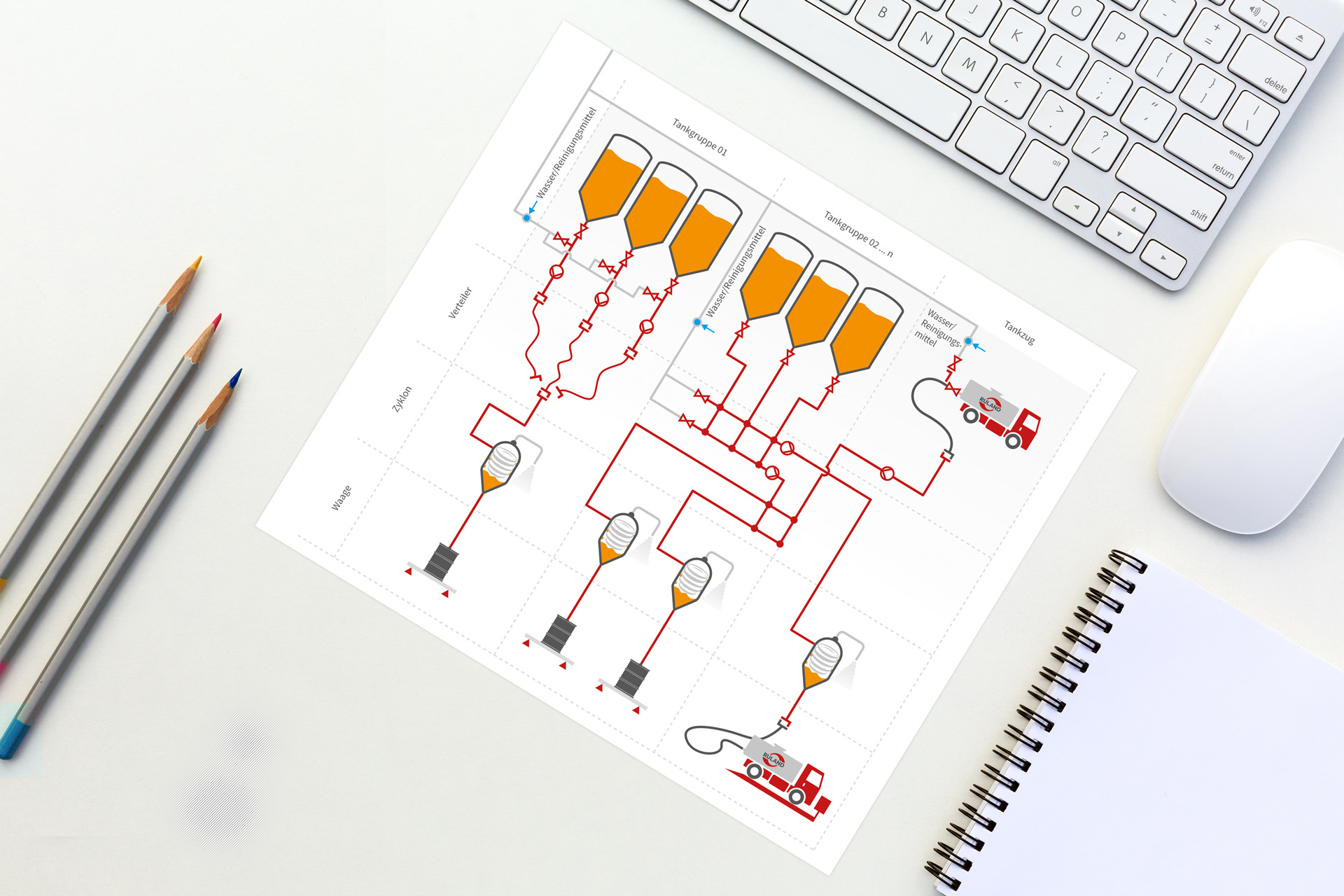

The pigging technology and the Whirlwind technology are deployed wherever pipelines need to be drained completely and without any losses. The benefits are clear: If batches and different products are separated cleanly, only a minimum of mixed phases occur and this obviously means less rejects. This not only reduces the costs for raw materials, cleaning agents and water but also the waste water load. With the pigging technology and whirlwind technology, significant savings can be achieved.

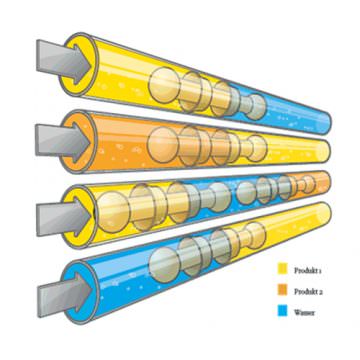

Pigging technology

The device is fed into the pipeline and it pushes out a specific route with identical nominal widths. However, it cannot pass through the most common standard fittings. The pigging system that is optimal for your plant or system depends on your products and processes. At Ruland, you can choose between manual or completely automated pigging systems, which include the respective sending and receiving stations and pigging cleaning systems. Incidentally, we also have piggable heating systems in our range of products!

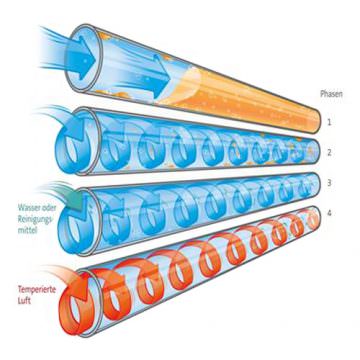

Whirlwind technology

The Whirlwind works without a compatible body that is pushed through the pipelines. It generates an air flow that drains pipelines using a multi-stage process and cleanly separates production batches from one another. However, our whirlwind can do much more: If required, it is able to thoroughly clean and dry lines with water and cleaning agents. The greatest difference compared to the pigging technology: Different pipe diameters are no obstacle for the whirlwind. Therefore, a Whirlwind system can supply many system modules simultaneously. For more information please see our Whirlwind flyer.

Click at the link below to activate the video. Please note that after activation your data will be submitted to the respective provider.

We would be delighted to advise you personally.

Would you like to learn more about yield optimization, pigging technology or whirlwind technology?

There are various applications for the separation of mix phases and the cleaing of pipes. One example is the