Efficient plant technology for protein hydrolysates

Resource-efficient production of proteins and protein hydrolysates

Ruland delivers innovative process engineering solutions that support the efficient extraction, processing, and refinement of proteins and protein hydrolysates from both plant and animal sources. The company provides a wide range of specialized plant components and systems including decanters, separators, filtration units and advanced cleaning technologies such as CIP (cleaning in place). By tailoring these technologies to specific applications, Ruland enables the production of high-quality proteins that meet the precise needs of various industries.

Removal of suspended solids: clarity right from the start

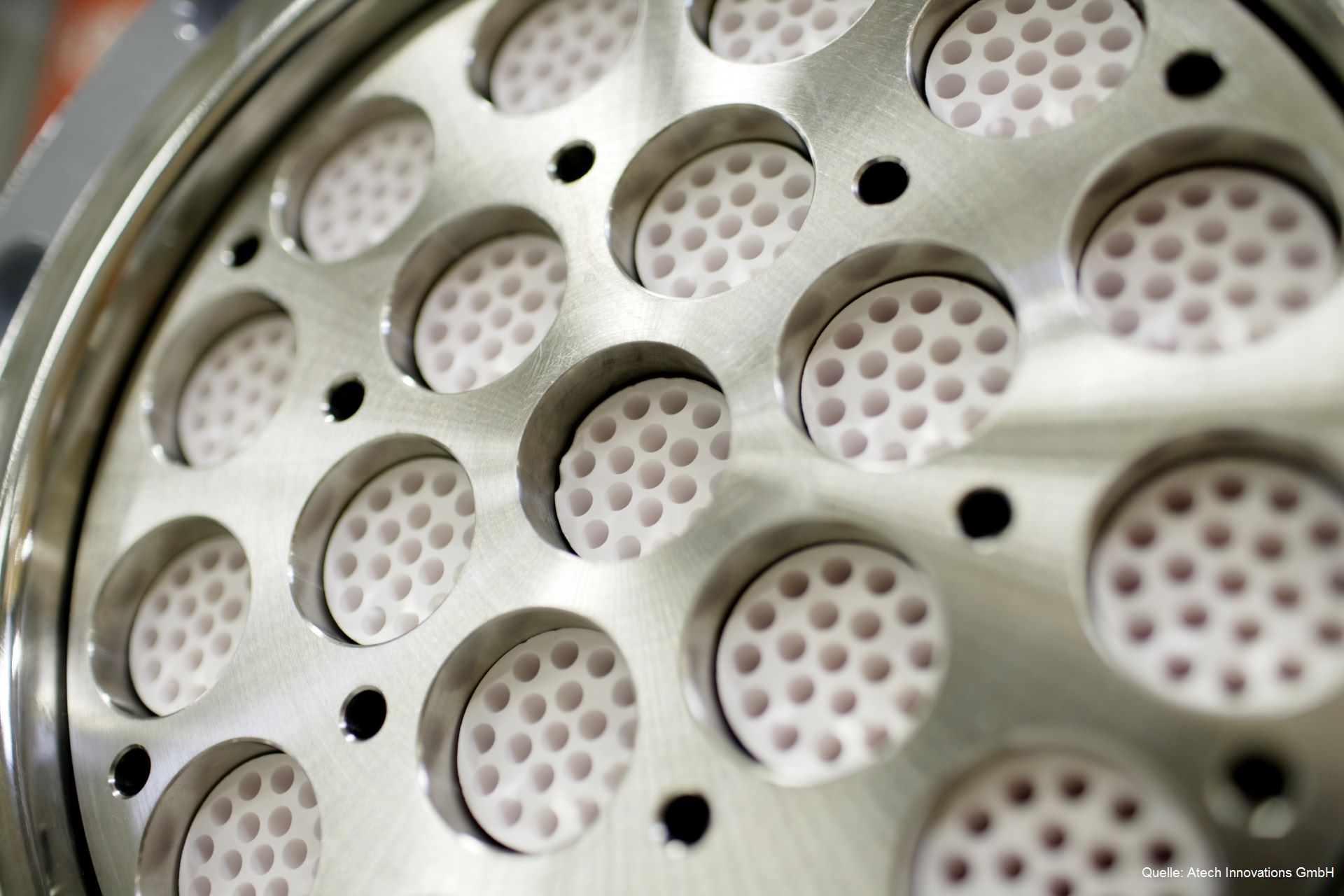

Decanters, separators and ceramic membranes separate proteins

Each step of the process demands precise expertise. From the initial separation of components to the final purification. Using decanters and separators, fats, water and proteins are efficiently separated, while solids and fats are systematically removed. To ensure optimal results, the equipment must be perfectly matched to the product characteristics, including the selection of suitable filters. For membrane filtration, choosing the ideal pore size is especially critical. This initial purification phase yields protein fractions of outstanding purity, laying a strong foundation for all subsequent processing steps. At the same time, it enhances process stability and improves product consistency and quality.

Desalinate effectively with diafiltration

Targeted improvement of taste, functionality and quality through modern filtration processes

Partial desalination plays a crucial role in achieving specific product qualities. To accomplish this, ultra- and nanofiltration membranes are used to effectively remove salts as well as unwanted flavors and odors. An additional diafiltration step enables further salt removal, helping to improve the product’s properties. This targeted process not only enhances the sensory characteristics of the protein but also improves its functionality in downstream applications, especially in the food- and pharmaceutical industries. By precisely controlling desalination, manufacturers can obtain proteins with optimal nutritional and functional profiles.

Concentration and drying: the optimal combination

Maximum efficiency in protein concentration

Ruland recommends the integration of evaporation techniques for further product concentration. This approach reduces the load on filtration membranes and enables a more compact evaporator design, conserving resources while maximizing product quality. By efficiently coordinating each process stage, energy consumption and operating costs are significantly reduced. The combined use of membranes and evaporators ensures loss-free processing, resulting in consistently high product quality and improved process reliability.

Controlled protein fractionation for defined chain lengths

Precise separation for versatile applications

Producing protein hydrolysates with specific chain lengths requires precise fractionation. In a multi-stage process, open membranes first remove large, long-chain molecules, while tighter membranes isolate short-chain proteins. This controlled separation makes a variety of chain lengths available for different applications. By fine-tuning the process, manufacturers can create protein hydrolysates with targeted functional properties. These tailored proteins are ideal for use in diverse sectors such as food, sports nutrition and medical products.

Filtration and cleaning

Resource-efficient water treatment

Efficient process water treatment is essential in water-intensive operations. Ruland optimizes this step by applying advanced filter and membrane technologies that significantly reduce organic contamination in wastewater. This approach enables up to 80% of the inflow volume to be recycled. By implementing this sustainable water management strategy, companies can reduce operating costs, minimize environmental impact and conserve valuable resources, all while maintaining high process efficiency.

Protein hydrolysate, protein solutions and their applications

From diverse protein sources for diverse applications

Proteins and protein hydrolysates are derived from a wide range of animal and plant sources, including beef, pork, poultry, eggs, fish, dairy products and various plants. Experts distinguish between hydrolyzed, digested and non-digested proteins, depending on the processing method and intended application. During hydrolysis, proteins are broken down into polypeptides, peptides and amino acids using specific enzymes. This process enables the production of hydrolysates such as fish protein hydrolysate and collagen hydrolysate, which are widely used in cosmetics, personal care products and dietary supplements like protein powders and bars for athletes. In contrast, whole protein solutions that remain largely unchanged retain their functional properties such as gel formation, foaming, and water-binding capacity. These protein isolates or concentrates often include pea protein, potato protein, fish protein, gelatin or whey protein. Many industries apply similar processing techniques, including the production of whey protein isolates, clarification and concentration of protein solutions, isoelectric precipitation through pH adjustment and the purification of proteins for pharmaceutical-grade applications. Protein production in fermenters also plays a key role in meeting high-quality standards across sectors.

Customised solutions for your protein production

Individual process plants for maximum efficiency and protein quality

Processing proteins requires customized plant solutions that go far beyond standard systems. At Ruland, we collaborate closely with our customers to ensure every plant component is perfectly aligned with the process. This enables us to design systems that deliver maximum efficiency and consistently high product quality. If you manufacture proteins or protein solutions, we invite you to share your specific process requirements with us. With decades of experience and deep technical expertise, we’re ready to help you identify the optimal solution for your needs. If you have any questions, please feel free and contact us any time.