RPSM: The Ruland Process Management System

Your customized and flexible MES for production control

The Ruland Process Management System (RPMS) was developed as a Manufacturing Execution System (MES) to optimize manufacturing processes and increase production efficiency. RPMS offers our customers customized solutions and records the entire production process in a higher-level software. It supports the production of liquids with raw material management, tank farm and container management as well as recipe handling and plant management. RPMS modularly controls, monitors and documents all production processes. The software is used for all Ruland systems in a wide range of industries.

RPMS is the link between commercial and technical systems

Individual development according to customer requirements

RPMS connects the commercial administration and ERP systems directly with the technology and the PLC controls of the systems. It enables direct communication with process automation and links individual system modules with each other. RPMS also exchanges relevant information with the ERP system and other production-related systems. The modules used by RPMS correspond exactly to the needs of the respective customer and are adapted accordingly. If an interface to ERP and technical systems is not yet available, it can be adapted individually. This means that RPMS is compatible with many systems and can be used flexibly.

The tasks of the RPMS

Transparent production planning and continuous flow of information

As higher-level software, the Ruland Process Management System records, controls and connects all processes that influence the manufacturing process. It communicates directly with the process automation and the PLC controls. With RPMS, users can manage raw materials for their production, save recipes and control production. A production overview shows all planned production orders with their current status. This means that they can be tracked at any time. The software supports production planning, records operating data and ensures complete traceability of production.

Modular structure of the Ruland Process Management System

With focus on your production processes

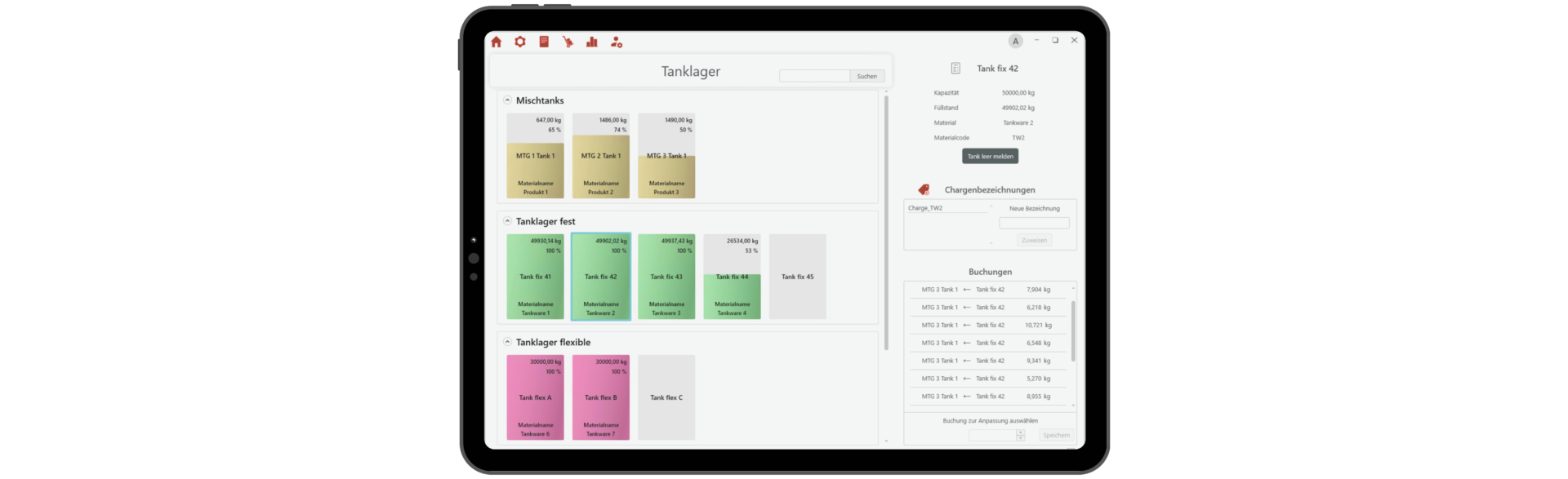

RPMS has a modular structure and adapts flexibly to your production flow. Thanks to its scalable structure, even small installations can benefit from RPMS and be expanded step by step as required. Our customers use RPMS to manage all process resources: they record raw materials, create recipes independently, store and prioritize procedural instructions and thus control the entire production process. RPMS can compile specific production processes from various recipes and quality features and manage tank farms efficiently. The mixing process can be controlled in batches from containers or tank systems. Cleaning processes (CIP) are also stored as recipes and integrated directly into production. RPMS makes it possible to maintain material stocks and make them available for other production modules. In addition, RPMS compares the data reported from the PLC with the ERP system to ensure seamless and precise integration of all production steps.

User-friendly interface and intelligent evaluation

RPMS supports paperless production

In addition to the Windows interface for administrative activities, RPMS has a web-based interface. This allows the software to be used flexibly at any location and on various devices (PC, mobile devices, etc.) and integrated into various visualization systems. The user-friendly, self-explanatory symbols of RPMS facilitate intuitive operation. The entire product flow is documented and can be traced at any time. RPMS covers a wide range, from batch-based and product- or time-related evaluations to individually compiled reports. All process values and process events, including faults and manual interventions, are recorded in detail in reports and diagrams, archived and displayed transparently. This enables simple and well-founded evaluation of the available data. Our RPMS developers design all diagrams and reports in individual layouts that enable customers to see all the information they need at a glance and proactively draw conclusions about possible process and production optimizations. RPMS also supports paperless production by providing fast digital access to all logs, approvals and statistics.

Devis plants are modernized with RPMS

Update for the syrup room

Existing DEVIS system control units, which are frequently used in the production of juices, juice concentrates and base materials, are reaching their limits: Their software systems are no longer supported, and there are neither software updates nor spare parts for the hardware. In addition, there are only a few experts left who can maintain these outdated systems. The Ruland Process Management System (RPMS) offers the solution here. It replaces the outdated software of the Devis systems with modern functions and can be integrated quickly and cost-effectively. This allows us to keep plant downtimes to a minimum.

RPMS: specialized, individual material and production management

Support for production processes and manufacturing

Through automated processes, RPMS increases productivity, minimizes manual intervention and reduces the susceptibility to errors, which leads to a significant increase in efficiency. RPMS also reduces administrative effort through automated data collection and logging, supports personnel scheduling and optimizes plant utilization. It manages several production lines and thus ensures precise production planning. Production-specific functions such as product mix calculations to achieve special quality characteristics or residual quantity functions to reduce waste reflect years of experience and production knowledge. Faults are also reported via the visualization software and documented by RPMS. Thanks to its flexibility and adaptability, RPMS integrates seamlessly into existing IT and production environments. It offers customized solutions that are tailored to the specific requirements and industry needs of our customers. With our extensive and cross-industry experience in plant engineering, we understand the production processes and know which functions are required for successful process control.

Let's talk about your specific Ruland Process Management System

Contact our team for expert advice

For comprehensive advice on the implementation and specific application of the Ruland Process Management System, please contact our specialist consultants. They will be happy to provide you with detailed information and customized solutions.