News

Read more about plant engineering, process plants, automation solutions etc.

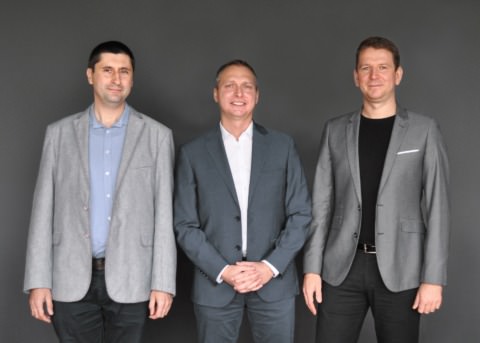

New managing directors at Ruland

10.02.2026

At the turn of the year, Bernhard Scheller and Jürgen Kutzer stepped down from active management at Ruland. We would like to say THANK YOU for 25 years of commitment, expertise, and passion. Both will remain with us as consultants.

Jürgen Schütze and Jens Schumann are taking over management together with managing partner Florian Klein. Jens and Jürgen are long-standing colleagues and bring with them extensive experience in process engineering, automation, project planning, sales, and digitalization. By promoting successors from within our own ranks, we are focusing on continuity, strength, and the sustainable development of our company.

Our claim remains: tailor-made process plants for innovative production processes.

We look forward to our future together!

Excellent sustainability

07.01.2026

Our company has been awarded the EcoVadis Silver Medal.

This award confirms our commitment to sustainability in the areas of the environment, labour and human rights, ethics and sustainable procurement – and motivates us to continue on this path.

For a strong future – for our team, our customers and our region.

Gentle concentration of plant extracts – preserving quality, unlocking potential

14.11.2025

The extraction and processing of high-quality plant extracts play a central role in the food, dietary supplement and cosmetics industries. Processes that preserve sensitive ingredients such as essential oils and green plant extracts while enabling economical processing are in particularly high demand. Gentle concentration is a crucial step in this process – it reduces volume, increases the density of active ingredients and creates the basis for stable, storable products.

But technology alone is not enough. The decisive factor is the tailor-made design of the process – tailored to the specific properties of the respective extract. Ruland sees itself not only as a plant manufacturer for tailor-made solutions, but also as a partner on equal terms – with the aim of achieving sustainable success together with our customers.

Ruland Poland wins innovation award for process solution in the beverage industry

22.10.2025

At the Polski Kongres Napojowy, our branch in Tychy was awarded first place in the “Step to Success” competition.

The award was given for our powder dissolution and dosing system, an innovative solution for beverage production. The module enables the efficient and reliable dissolution of powders in liquids. It thus contributes to quality improvement, process reliability, and energy efficiency in production. The award confirms our approach to flexible, customer-oriented solutions in process and process engineering.

We would like to thank the organizers of the competition, our customers, and partners for their trust and the award. Together with our team, we will continue to work on innovative ideas for plant engineering.

drinktec 2025

15.07.2025

It’s just two months away: drinktec 2025 kicks off in Munich on September 15.

We at Ruland Engineering & Consulting will of course be there again with our exhibition booth!

📍 Hall B5, booth B5-204

Come by and discover our powder dissolving station live on site. You can find more information about our systems for dissolving powder and efficient dosing on our website:

👉 https://rulandec.com/en/process-technology/powder-dissolving-dosing/

✔️Use the voucher code DRI25RULAND to receive free admission on all days of the trade fair.

AuditTrail for Biotest – Modern traceability for greater safety and quality

23.06.2025

For our customer Biotest AG, we are integrating an audit trail into the control system of an existing plant. In future, every change to controllers, scales, parameters, valves, or drives at the plant can be tracked, displayed, and printed out. Comment functions for predefined changes facilitate analysis and traceability.

The implementation was challenging and required customized solutions, comprehensive adjustments, and extensive testing in some cases. Thanks to the excellent cooperation with Biotest, all requirements were clearly defined and implemented quickly.

All changes are thoroughly tested in advance on our internal test system together with Biotest. The final implementation takes place specifically during the maintenance window in summer – for minimal downtime and maximum safety.

This is how we at Ruland combine technical expertise with customized solutions – for maximum product quality and safety.

Ruland celebrates 25 years of success story

28.02.2025

25 years of Ruland – We love liquids

Ruland celebrates 25 years of innovation in plant engineering and design! Since 2000, we have stood for customised process systems, the highest hygiene standards and reliable solutions. A small team has grown into an international company with 320 experts. As a family business, we are proud to look to the future – together with our customers and partners.

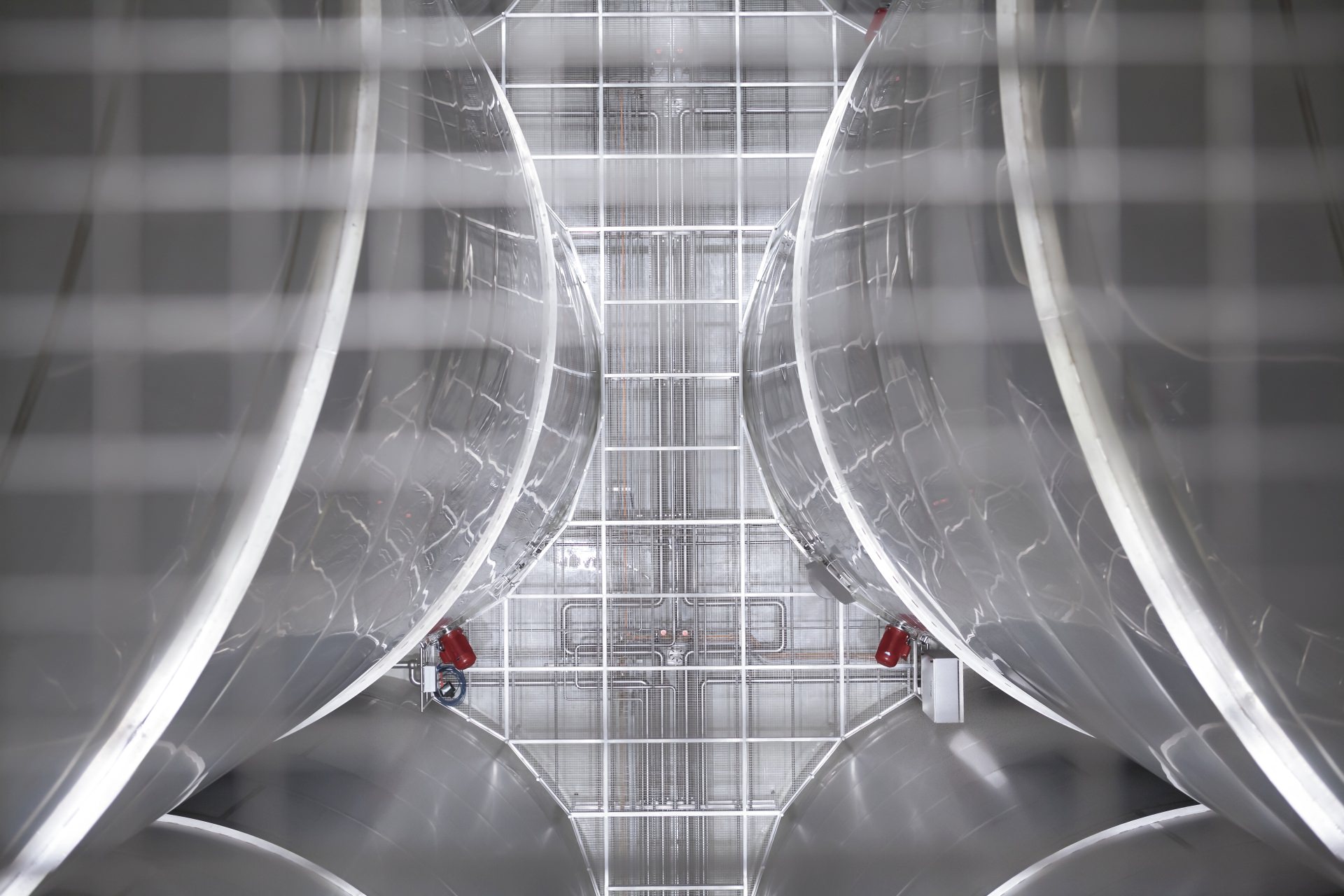

Hygienic design system gets additional vessels

11.02.2025

A long-standing customer in the pharmaceutical sector wanted to increase its production capacities significantly. To this end, the customer ordered new production containers with an operating platform and system technology in hygienic design. The challenge of the project was the installation during ongoing production. This required extensive pre-planning and precise, comprehensive prefabrication. Find out more about the project.

Virtual reality – a valuable tool for industry?

04.11.2024

Industrial transformation known as Revolution 4.0, with its focus on the automation and digitalization of industrial processes, has led to fundamental changes in the way products and services are designed, manufactured, managed and delivered.

Digital prototyping and simulation, automation and robotics, additive manufacturing, big data, AI and virtual reality are just part of the revolution. The changes are a reaction to the individual needs of the modern customer and the omnipresent trend towards the personalization of products and services. Ruland uses innovative tools and technologies in its projects.

New members on the Ruland Management Board

11.09.2024

From young professionals to managing directors: Jürgen Schütze and Jens Schumann have been appointed to the management of Ruland Engineering & Consulting GmbH with immediate effect.

Jürgen and Jens have both been committed Ruland employees for many years. We are particularly proud that we can fill these positions from within our own ranks – a strong sign of the continuous development within the company!

We look forward to a successful future with you and the next steps!

Plant automation

28.03.2023

The automation of industrial plants found its way into manufacturing companies with the digital revolution in the 1970s. Today, we no longer deliver any plant without an automated control function. Even if IoT and full networking of man and machine still seem a long way off in reality, the trend is clearly moving towards collection, storage and intelligent evaluation of more and more data in real time.

New management in Ruland Tychy

20.01.2021

The beginning of 2021 brings a change to Ruland Tychy. A new management team took the reins at the beginning of this year. The new managing directors come from the long-standing staff in Tychy. As employees and later in managerial positions, they have actively helped to shape the modern structures in Tychy. Our managers know our potential in terms of organisation, team and plant construction very well and are working with full vigour to develop this further.

Our new management in Tychy:

Bartłomiej Berger, Director Process Automation

Piotr Cieplinski, Managing Director

Marek Winkler, Technical Director

(from left to right)

New production facilities in Poland

08.10.2020

Ruland Tychy has expanded its production area with the construction of a new production hall. The decision to build a new hall is a response to growing demand and an increased need for production space for larger plant modules. The modern equipment of the new hall offers improved working conditions for our employees and efficient handling in the production process up to loading of the plants.

The Rulanders introduce themselves

07.05.2020

Some Ruländer introduce themselves. Find out more about some personalities in our multi-faceted Rulander-team.