Plant design and process technology

These 10 Punkte form the basis of your process unit

Tailormade plant engineering is about many details

What you need to consider for your enquiry on process engineering and plant design.

A qualified offer on process plants is based on many aspects. Check what we need to fix in a briefing regarding your quotation. A quick budget or detailed quotation: In the following you’ll find a guideline. The more information we have, the better idea we get of your requirements on process technology. Send us these details together with your enquiry. We’ll get back to you, directly with a first budget or with even more questions.

Is it the opposite? You already have a comprehensive concept and are not sure what solution will be best for you in the long term? – Let’s check details together in a consulting project! This way, we’ll find the best approach for your production system.

1. Description of the project „process unit“

Describe your plant building project and your focus.

Please think about the overall goal you want to reach with the plant, as „higher production capacity“, „better product quality“, „higher level of hygiene”, “longer life cycle”.

Also important to know: The project place.

2. Product

Characterize your product that will be processed by the plant system.

Do you need the process plant for food, pharmaceuticals, body and health care products, biotechnological products or other? What will you produce with the process plant? Will you produce various products and product variations? Will you have many product changeovers?

3. (Raw) materials

Focus the basics for your production unit.

What raw materials do you use for your production? In what condition and quantity do you get them? In what packages do you store them, and in what packages do you bring them into the process (i. e. container, IBC, bag)? What are the chemical and physical characteristics of the materials (i. e. concentration, viscosity)? Also inform us on the characteristics of your final product.

4. Capacity of the unit

Give us details on the process technology and your plants.

What capacity, flow rate and other output levels shall the future unit have? How big are your batches? Is there any time limit to process them? Are there any variations in production?

Please also consider future requirements. This is important for the plant engineering.

5. Plant engineering, process and rooms

Explain the process and the room situation. Both points influence the plant design.

An overview of the existing process is important to include the unit into an existing production system. For assessment of the space available, a plan of the building helps. Further, should you plan a completely new production process, any information on your facility components is helpful. If you want us to check your inventory of technology, just let us know.

6. Existing plant systems

Geben Sie uns eine Übersicht an Ihrem Bedarf für Anlagenmontage, Einbindung, Schnittstellen und Give us an overview on your needs for plant assembly, integration of plant, interfaces and demounting of process systems.

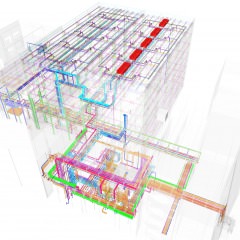

Do you wish the supply of new unit parts solely? Shall we integrate the new process technology in existing plant systems? Do you have any P&IDs? The more details we have, the quicker our planning is. Are there any interfaces with other unit parts? Please also consider existing system. Who does the dismantling, if necessary? Who’s organizing transport? For these tasks you should work with qualified welders, fitters and supervisors.

7. Engineering of plants

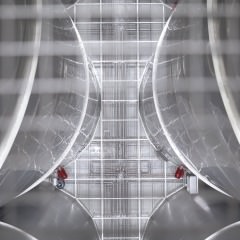

Think about your requirements on the engineering as hygienic design, plant construction details etc.

We have to consider many details when doing basic and detail engineering of your processing system. Individual requirements, hygienic design of the unit, easy access to the plant modules, easy handling, programming of sequences, design of control and load cabinets and many other points.

8. Process automation

Specify process control.

What level of automatization do you need? What functions should be automatically controlled? How does your visualization look like? What are your needs on documentation and recording of data?

9. Standard components

Name us your standards.

Do you have any standard components on process technology or automation parts?

10. Long-term objectives

Please take a moment to think about your medium- and long-term planning.

What is your production goal in 5 or 10 years? Are you planning any additional products in your product offer? Do you have an increased sales volume and higher production capacities in mind? Let’s consider these ideas in our basic planning as possible upgrades.

There are many options for plant design and process technology.

The more details you give us, the more custom-fit your quotation will be.

Many points of your production plans are still open? – Let’s work out details together!